Bolting technology and torque wrenches

Torque wrenches are used wherever bolted joints must be tightened precisely, safely and reproducibly. In industrial applications, energy and plant engineering, or series production, exact torque control is essential for quality, safety and process stability.

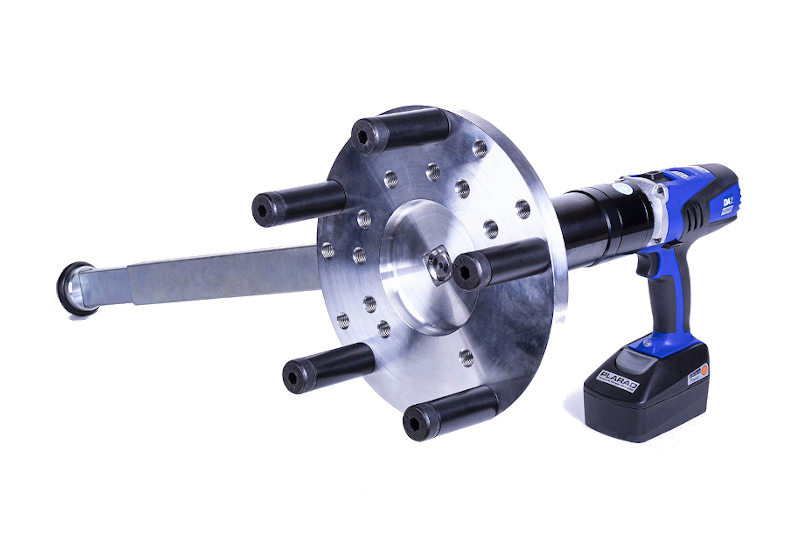

PLARAD offers a broad range of torque wrenches designed to meet different requirements – from compact battery-powered torque wrenches for flexible applications to hydraulic high-performance torque wrenches for extremely high torque levels. The various designs differ in terms of drive technology, performance range, precision and typical fields of application.

Below you will find an overview of the different types of torque wrenches and their respective application areas, helping you identify the right solution for your specific application.